| Aeronautica | Comunicatii | Constructii | Electronica | Navigatie | Pompieri |

| Tehnica mecanica |

Sudarea cu arc electric - referat

Sudarea este operatia tehnologica prin care se realizeaza o asamblare nedemontabila a doua piese metalice (cu compozitii apropiate) prin topire sau presiune, cu sau fara material de adaos.

Elementele care se sudeaza (table, profile, etc.) se prelucreaza, in prealabil, la marginile ce vor fi sudate, obtinindu-se un spatiu de dimensiuni reduse numit rost.. In urma aplicarii procedeului de sudare rezulta o cusatura sau un cordon de sudura.

Sudura cu arc electric este un procedeu de imbinare a pieselor metalice prin topire, cu material de adaos, temperatura necesara realizarii imbinarii obtinindu-se prin crearea unui arc electric intre electrodul de sudura si piesa de imbinat. In acest proces energia electrica este transformata in caldura, metalul topindu-se si astfel realizindu-se imbinarea dupa racire si revenirea in stare solida.

Incepind cu anii 1800 au existat mai multe incercari si studii in domeniul sudurii cu arc electric. In anul 1865 un englez pe nume Wilde obtine primul patent pentru sudura electrica. El a reusit unirea a doua piese de metal cu ajutorul curentului electric, incalzirea obtinindu-se prin trecerea curentului direct prin cele doua piese. Aproximativ douazeci de ani mai tarziu omul de stiinta de origine rusa Bernado, a obtinut primul brevet pentru sudura cu arc electric. El a obtinut un arc electric intre un electrod de carbon si piesele de asamblat, fixand piesele impreuna pe masura ce arcul electric era trecut manual peste imbinarea sudata.

In ani 1890, sudura cu arc electric a inceput sa fie utilizata pe scara industriala pentru imbinarea pieselor metalice. La inceput sudura se realiza cu electrod din metal neacoperit, care in urma topirii devenea material de adaos pentru imbinare. Sudurile erau de proasta calitate datorita oxigenului si azotului din atmosfera care forma oxizi in materialul sudurii. De aceea in aceasta perioada sudura nu era folosita pentru elemente cu solicitari mari, pentru acestea asamblarea nituita ramanand cea mai des folosita. La inceputurile secolului douazeci a fost constientizata importanta protejarii arcului de gazele din atmosfera. Acoperirea electrodului cu un material ce se evapora in timpul procesului de sudare si formeaza um mediu gazos protector a fost considerata a fi cea mai buna solutie la acel moment. Ca urmare diverse metode de acoperire a electrozilor au fost folosite. Eforturile au culminat cu realizarea electrozilor acoperiti prin extrudare la mijlocul anilor 1920, calitatea imbinarii sudate crescand spectaculos. Incepand cu aceasta perioada sudura cu arc electric devine din ce in ce mai folosita ajungand cel mai des utilizat procedeu de asamblare nedemontabila.

Deoarece sudura cu electrod acoperit este o procedura destul de lenta, in ultima perioada au fost dezvoltate proceduri de sudare cu arc electric mult mai rapide.

II. Clasificarea asamblarilor sudate

II.1. Dupa modul de realizare

Sudare prin topire

La randul lor dupa modul de topire al materialului pot fi:

-cu flacara

-electrica

Sudare prin presiune

II. 2. Dupa materialul de adaos

Cu material de adaos

Fara material de adaos

II.3. Dupa pozitia elementelor de sudat

Cap la cap

Suprapusa

De colt

Pe muchie

In T

II.4. Dupa forma geometrica a rostului in sectiune transversala

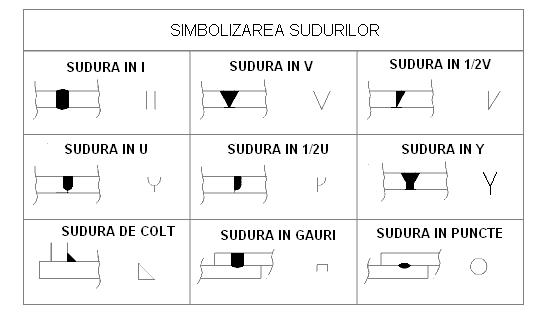

In I

In V

In U

In Y

In gauri

II.5. Dupa continuitatea cordonului de sudura

Sudura continua

Sudura in puncte

II.6. Dupa forma exterioara a cordonului de sudura

Plana

Convexa

Concava

III. SUDURA CU ARC ELECTRIC

In prezent exista mai multe metode de sudare cu arc electric. Dintre acestea doua sunt cele mai des utilizate si anume:

Sudura cu arc electric cu electrod acoperit.

Sudura in mediu protector de gaz.

III.1. Sudura cu arc electric cu electrod acoperit

Sudura cu arc electric cu electrod acoperit este cel mai des utilizat procedeu de sudura. Sudura este realizata prin caldura degajata de un arc electric mentinut intre intre capatul electrodului acoperit si piesele de imbinat. Caldura produsa de arcul electric topeste metalul de baza, miezul electrodului si materialul de acoperire a electrodului. In timpul transferarii picaturilor de metal topit de la electrod la imbinare aceste sunt protejate de gazele oxidante din atmosfera prin intermediul mediului gazos protector obtinut ca urmare a evaporarii materialului invelisului electrodului. De asemenea materialul protector topit pluteste peste sudura protejind-o pana la solidificarea acesteia.

Alta functie a acoperirii electrodului este aceea de a conferi o mai buna stabilitate arcului electric si un mai bun control asupra formei sudurii.

III.1.1. Echipamente si tehnologia de lucru.

Unul din motivele largii raspandiri a procedeului de sudare cu electrod acoperit este simplitatea echipamentului necesar sudarii. Echipamentul se compune din urmatoarele (vezi figura):

Sursa de sudura

Suportul electrodului

Clema de masa

Cabluri si conectori

Echipamente auxiliare (ciocan pentru indepartat zgura, perie de sarma)

Echipamente de protectie (masca de sudor, manusi, sort etc.)

1. Sursa de sudura

Sudura cu arc electric protejat poate utiliza fie curent continuu fie curent alternativ, dar in ambele cazuri sursa trebuie sa fie cu reglaj in curent constant. Acest tip de sursa livreaza un curent de intensitate relativ constanta, indiferent de lungimea arcului electric data de operator. Intensitatea curentului determina cantitatea de caldura degajata de arcul electric, si deoarece este constanta sudura va fi uniforma ca marime si forma indiferent de variatiile lungimii arcului electric. Decizia de utilizare a surselor de curent alternativ sau continuu depinde de tipul de sudura ce trebuie realizat si de tipul electrodului folosit. Majoritatea electrozilor sunt conceputi astfel incit sa poata fi folositi atit in curent continuu cit si in curent alternativ, totusi exista si electrozi care nu pot fi folositi decit in curent continuu. Un alt factor de decizie privind tipul de curent utilizat este grosimea materialului. Sursele de curent continuu se pot utiliza atit pentru grosimi mici cit si pentru grosimi foarte mari. Pentru table mai subtiri se prefera curentul continuu pentru ca arcul electric poate fi mentinut mai usor la curenti mai mici.

2. Suportul electrodului

Suportul electrodului se conecteaza la cablul de sudura si conduce curentul electric catre electrod. Manerul izolat este folosit pentru a ghida electrodul peste imbinare si apropierea electrodului de baia de sudura pe masura ce acesta se consuma. Suporturile de electrod sunt de diferite tipuri si marimi si se prezinta de obicei sub forma unui cleste.

an explosion and fire risk, some common precautions include limiting the amount of oxygen in the air and keeping combustible materials away from the workplace

Ground Clamp - The ground clamp is used to connect the ground cable to the work piece. It may be connected directly to the work or to the table or fixture upon which the work is positioned. Being a part of the welding circuit, the ground clamp must be capable of carrying the welding current without overheating due to electrical resistance.

Welding Cables - The electrode cable and the ground cable are important parts of the welding circuit. They must be very flexible and have a tough heat-resistant insulation. Connections at the electrode holder, the ground clamp, and at the power source lugs must be soldered or well crimped to assure low electrical resistance. The cross-sectional area of the cable must be sufficient size to carry the welding current with a minimum of voltage drop. Increasing the cable length necessitates increasing the cable diameter to lessen resistance and voltage drop. The table in Figure 4 lists the suggested American Wire Gauge (AWG) cable size to be used for various welding currents and cable lengths.

Coated Electrodes - Various types of coated electrodes are used in shielded metal arc welding. Electrodes used for welding mild or carbon steels are quite different than those used for welding the low alloys and stainless steels. Details on the specific types will be covered in subsequent lessons.

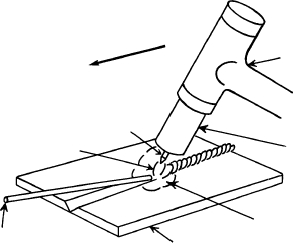

GAS TUNGSTEN ARC WELDING Gas Tungsten Arc Welding* is a welding process performed using the heat of an arc established between a nonconsumable tungsten electrode and the work piece. See Figure 5. The electrode, the arc, and the area surrounding the molten weld puddle are protected from the atmosphere by an inert gas shield. The electrode is not consumed in the weld puddle as in shielded metal arc welding. If a filler metal is necessary, it is added to the leading the molten puddle as shown in 2.3.0.1 Gas tungsten arc welding produces exceptionally clean welds no slag is produced, the chance inclusions in the weld metal is and the finished weld requires virtually no cleaning. Argon and Helium, the primary shielding gases employed, are inert gases. Inert gases do not chemically combine with other elements and therefore, are used to exclude the reactive gases, such as oxygen and nitrogen, from forming compounds that could be detrimental to the weld metal. Gas tungsten arc welding may be used for welding almost all metals - mild steel, low alloys, stainless steel, copper and copper alloys, aluminum and aluminum alloys, nickel and nickel alloys, magnesium and magnesium alloys, titanium, and others. This process is most extensively used for welding aluminum and stainless steel alloys where weld integrity is of the utmost importance. Another use is for the root pass (initial pass) in pipe welding, which requires a weld of the highest quality. Full penetration without an excessively high inside bead is important in the root pass, and due to the ease of current control of this process, it lends itself to control of back-bead size. For high quality welds, it is usually necessary to provide an inert shielding gas inside the pipe to prevent oxidation of the inside weld bead.

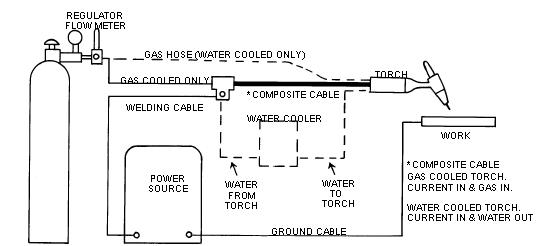

Gas tungsten arc welding lends itself to both manual and automatic operation. In manual operation, the welder holds the torch in one hand and directs the arc into the weld joint. The filler metal is fed manually into the leading edge of the puddle. In automatic applications, the torch may be automatically moved over a stationary work piece or the torch may be stationary with the work moved or rotated in relation to the torch. Filler metal, if required, is also fed automatically. EQUIPMENT AND OPERATION - Gas tungsten arc welding may be accomplished with relatively simple equipment, or it may require some highly sophisticated components. Choice of equipment depends upon the type of metal being joined, the position of the weld being made, and the quality of the weld metal necessary for the application. The basic equip- ment consists of the following: The power source Electrode holder (torch) Shielding gas Tungsten electrode Water supply when necessary Ground cable Protective equipment

Power Sources - Both AC and DC power sources are used in gas tungsten arc welding. They are the constant current type with a drooping volt-ampere curve. This type of power source produces very slight changes in the arc current when the arc length (voltage) is varied. Refer to Lesson I, Section 1.9. The choice between an AC or DC welder depends on the type and thickness of the metal to be welded. Distinct differences exist between AC and DC arc characteristics, and if DC is chosen, the polarity also becomes an important factor. The effects of polarity in GTAW are directly opposite the effects of polarity in SMAW as described in paragraphs 2.2.2.3 through 2.2.2.5. In SMAW, the distribution of heat between the electrode and work, which determines the penetration and weld bead width, is controlled mainly by the ingredients in the flux coating on the electrode. In GTAW where no flux coating exists, heat distribution between the electrode and the work is controlled solely by the polarity. The choice of the proper welding current will be better understood by analyzing each type separately. The chart in Figure 7 lists current recommendations.

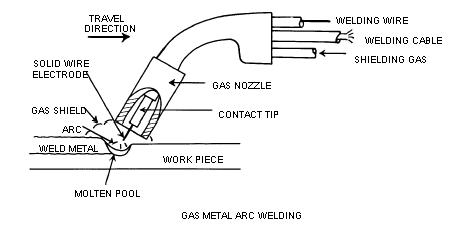

GAS METAL ARC WELDING Gas Metal Arc Welding* is an arc welding process that uses the heat of an electric arc established between a consumable metal electrode and the work to be welded. The electrode is a bare metal wire that is transferred across the arc and into the molten weld puddle. The wire, the weld puddle, and the area in the arc zone are protected from the atmosphere by a gaseous shield. Inert gases, reactive gases, and gas mixtures are used for shielding. The metal transfer mode is dependent on shielding gas choice and welding current level. Figure 9 is a sketch of the process showing the basic features.

Gas metal arc welding is a versatile process that may be used to weld a wide variety of metals including carbon steels, low alloy steels, stainless steels, aluminum alloys, magnesium, copper and copper alloys, and nickel alloys. It can be used to weld sheet metal or relatively heavy sections. Welds may be made in all positions, and the process may be used for semiautomatic welding or automatic welding. In semiautomatic welding, the wire feed speed, voltage, amperage, and gas flow are all preset on the control equipment. The operator needs merely to guide the welding gun along the joint at a uniform speed and hold a relatively constant arc length. In automatic welding, the gun is mounted on a travel carriage that moves along the joint, or the gun may be stationary with the work moving or revolving beneath it. Practically all GMAW is done using DCEP (Electrode positive). This polarity provides deep penetration, a stable arc and low spatter levels. A small amount of GMAW welding is done with DCEN and although the melting rate of the electrode is high, the arc is erratic. Alternating current is not used for gas metal arc welding.

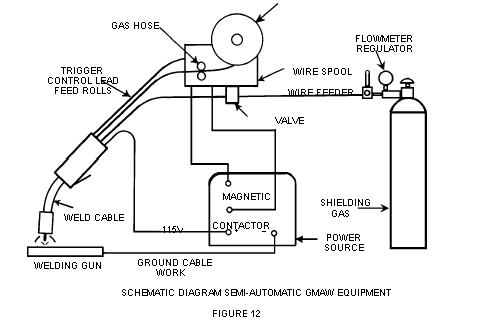

EQUIPMENT AND OPERATION - The equipment used for gas metal arc welding is more complicated than that required for shielded metal arc welding. Initial cost is relatively high, but the cost is rapidly amortized due to the savings in labor and overhead achieved by the rapid weld metal deposition. The equipment necessary for gas metal arc welding is listed below: 1) Power source 2) Wire feeder 3) Welding gun 4) Shielding gas supply 5) Solid electrode wire 6) Protective equipment

Welding, without the proper precautions, can be a dangerous and unhealthy practice. However, with the use of new technology and proper protection, the risks of injury and death associated with welding can be greatly reduced. Because many common welding procedures involve an open electric arc or flame, the risk of burns is significant. To prevent them, welders wear protective clothing in the form of heavy leather gloves and protective long sleeve jackets to avoid exposure to extreme heat and flames. Additionally, the brightness of the weld area leads to a condition called arc eye in which ultraviolet light causes the inflammation of the cornea and can burn the retinas of the eyes. Goggles and helmets with dark face plates are worn to prevent this exposure, and in recent years, new helmet models have been produced that feature a face plate that self-darkens upon exposure to high amounts of UV light. To protect bystanders, transparent welding curtains often surround the welding area. These curtains, made of a polyvinyl chloride plastic film, shield nearby workers from exposure to the UV light from the electric arc, but should not be used to replace the filter glass used in helmets.[39]

Welders are also often exposed to dangerous gases and particulate matter. Processes like flux-cored arc welding and shielded metal arc welding produce smoke containing particles of various types of oxides, which in some cases can lead to medical conditions like metal fume fever. The size of the particles in question tends to influence the toxicity of the fumes, with smaller particles presenting a greater danger. Additionally, many processes produce fumes and various gases, most commonly carbon dioxide and ozone, that can prove dangerous if ventilation is inadequate. Furthermore, because the use of compressed gases and flames in many welding processes pose

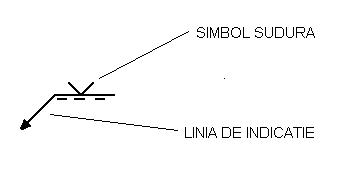

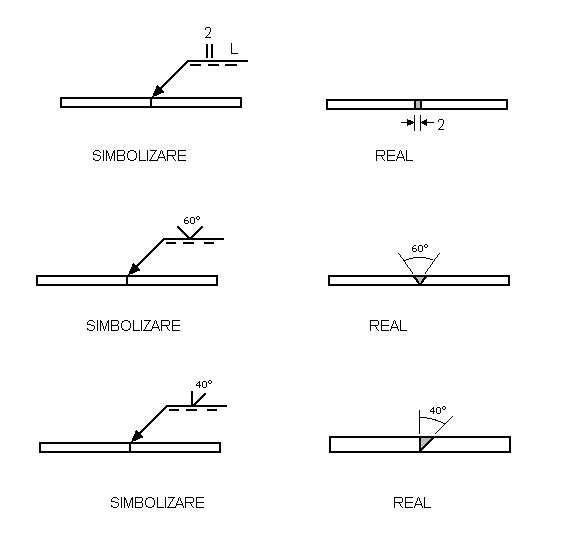

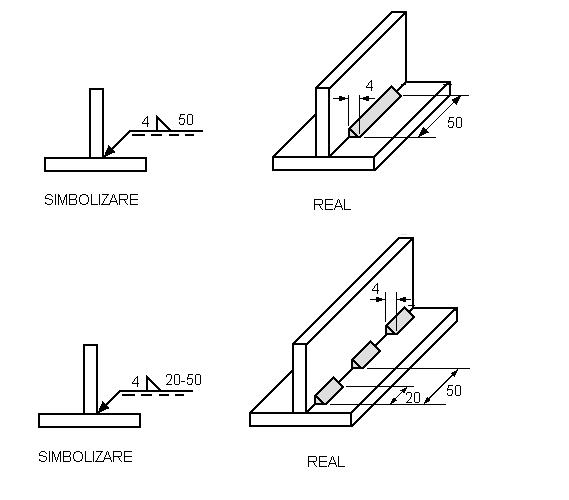

Notarea sudurilor pe desenele tehnice se face prin intermediul unei linii de indicatie ce se termina cu o sageata ce se sprijina pe cordon. Pe aceasta linie de indicatie se noteaza simbolul sudurii, simbolurile suplimentare si dimensiunile sudurii.

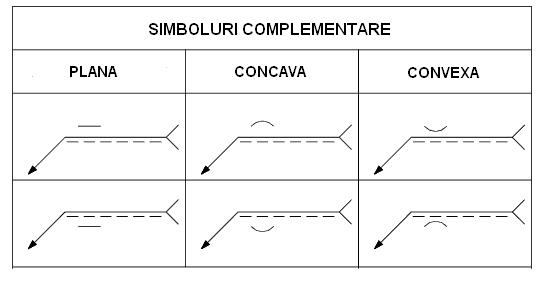

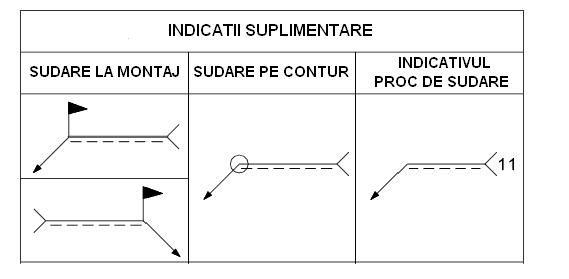

In tabelele de mai jos se pot vedea simbolurile de baza si simbolurile suplimentare folosite la notarea sudurilor.

Inscrierea cotelor se face astfel :

Cotele legate de pozitionarea cordonului de sudura in raport cu marginea piesei se inscriu direct pe desen.

1. AVANTAJE

a. Economia de metal

Folosirea costructiilor sudate asigura o importanta economie de metal in comparatie cu piesele turnate sau nituite. Aceasta economie se obtine in special datorita :

Datorita proprietatilor foarte bune a materialelor ce se sudeaza si a eliminarii pieselor intermediare, constructiile sudate sunt mai usoare decat alte tipuri de costructii metalice

Date din faptul ca nu necesita utilaje scumpe. De asemenea se realizeaza si o economie de energie fata de cazul pieselor turnate unde se topeste o cantitate de metal mult mai mare.

2. DEZAVANTAJE

Principalul dezavantaj al imbinarilor sudate este dat de faptul ca au o calitate ce depinde foarte mult de pregatirea si atentia operatorului. Rezulta nevoia de personal foarte calificat si o posibilitate mai greoaie de control a calitatii procesului. Totusi acest dezavantaj este eliminat in cazul instalatiilor automatizate de sudura.

Copyright © 2025 - Toate drepturile rezervate